User:Dmitry G/gallery/Electricity/e-college

Electrcity for educational institutions[edit]

As usual, I'm trying to require high knowledges. Cause really qualified specialist should justify his qualification by knowledges. In West-Europe colleges requiring only wire clamping in terminals. But I spend only 3 or 4 hours to teach trainees how to push wire to the terminal and clamp it there. All rest time they show to me how they learned to wire various appliences.

- Kirchhoff's circuit laws are perfectly explained here.

Electrical engineering[edit]

To avoid those situations =)

Where are problems? The biggest problem is "divorced" theoretical part from experimental part. Such way, after graduating, licensed person can't do any correct actions even on simple works. Some very "competent" persons threat this problem by requirement to work after graduating for some years under someone's supervision. But modern tendances of living put company owners to employee only experienced persons, who able to work 24 hours per day without weekend and for smallest salary or without salary.

As lot of questions are not considered due to evidence, theoretical part are given without experimental part, here are given some missing chain's units of knowledges. I fight with this uneducation approximately 3 years, but however trade union of electrical companies throw a monkey wrench into my side cause I'm producing their competitors, who will leave them without work.

Be ready to be tested by your life after graduating ;-)

-

Ohm's law for full circuit

-

Ohm's law in real

-

How to calculate parameters

-

Magnetism (very important)

-

How does European network work

-

What should know really qualified electrician. Cause wire clamping in terminal requires no brian or qualification at all.

-

Haven't you ever seen this situation - you turn vacuum cleaner on, but lamps begin to blink? Especially it is notable in old houses.

-

How to understand, what cable is it?

-

European color codes

-

How to wire RCBOs. RCD are the same, but you should also add circuit breaker before.

-

How to NOT wire RCDs or why I don't attach ground wire to neutral in my panel

-

Why all hot wires should be symmetrically loaded?

-

Vector diagrams for AC.

-

Power triangle and cosф.

-

Derivative-integral table. How to take an integral? Take result from y' to y and add constant.

-

Transients

-

That is why I prefer Schneider circuit breakers, always trip intime.What for is created circuit breaker? -

Well, terminals are copper, I can't use them in old buildings where wires are aluminium.Way of their work. -

What should you consider working with LED lights

-

Junction box

-

Junction box

-

Light switch and fitting box

-

Example of sorting cable salad caused by using one box as outlet and junction boxes.

-

How to install electric soves or boilers

As you see, I'm not ratifying specialists, who's skills are limited by replacing light switch or some other work where brain is not required at all. Maybe laws in many countries are protecting laymans against losing their job. But I don't take care about it at all. Also, it is second reason, why I don't wish to talk with electrical safety boards at all. Cause major of licensed by them specialists can't design nuclear power plant or something else like this. Guess, how many of those specialist know about Kirchhoff's circuit laws? Or how many specialists may calculate the circuit? It'll be lucky, if 1 specialist from 10.

Real installations[edit]

This material is not taught in many colleges/universities. That is why lot of graduated persons fail searching work, cause nobody told about it and graduated persons have no related knowledges in working with installations. For example, British authorities produce big number of cowboy specialists and they can't understand (or lie themself) why there appear so many cowboys. And of course, they don't want to change anything to solve problem from inside or do anything to improve situation. In this situation better to turn power off in whole kingdom and resort to the use the torches and bonfires like it was in the middle ages.

-

How does electricity go to the consumer?

-

Modern way of separating between consumer and your energy company. But safety has lot of questions.

-

Equipotential bonding

-

Multipoint ground. Remember: all open metal parts should be connected with ground wire.

Conclusions[edit]

- 1) Power must be off before work. Hot wires should be shorted to the ground while you're working. If there are skin-burn risks due to high short-circuit current (like in factory), you should disconnect disenergized wires from circuit breaker and connect to earth busbar.

- 2) Wiring must be done according to wiring rules and building codes in your region! Wires and cables should be lined nice without salad. If you install 16A receptacle, there should be 16A cable and 16A circuit breaker; otherwise you risk to make fire. Bathrooms should be wire according to safeguard zones: 12 Volts near water and mains voltage through RCD/GFCI protected on 2.25 meters from water with IP44 rate.

- 3) After work is done, all metal covers should be connected with ground; if ground wire is missing (like old installations) there must be dielectric covers.

- 4) If all metal parts are grounded and all covers been installed - you may switch hot wires from earthing busbar to circuit breakers and then turn power on. If there is risk to get skin burn due to high short-circuit current, you should install cover to fuse box first and only then turn power on.

To supply safety[edit]

- 1) Grounding:

- 1.1) TN-C - when neutral wire is used as the ground wire. Nowadays this system is not allowed. TN-C might be used only in appliences, which have no neutral wire (like motors). But in old Soviet houses you may see neutral attached to fuse box cover and all grounding wires are connected with neutral. So, PEN-conductor (Protection Earth + Neutral) have been divided into protecting neutral and working neutral near consumer. In this case, if PEN is broken, all neutralled metal parts will have lethal voltage on them. That is why cheap TN-C went down in history and not used in new installations.

- 1.2) TN-S - when neutral and ground wires are divided in distribution substation. In this case, if neutral wire is broken, all metal parts will have safe for human 0 volts. But it is very expensive and used only in Great Britain.

- 1.3) TN-C-S - is widespread system. Your retail company uses neutral wire as the ground wire, but PEN-conductor is divided in main panel. This way your retail company has TN-C system, but you have TN-S at your home. That way, neutral wire should be grounded in your main panel one more time.

- 1.4) TT - when ground is used as the ground wire. It's recommended to use near explosives where sparks are danger. Big disadvantage: it will be useless without working RCD/GFCI, so lot of countries forbit it.

- 1.5) IT - when neutral is ungrounded. This system is used in the hospitals, but requires earth leakage signalisation.

- 2) Safety classes:

- 2.1) 0 class - ungrounded device with metal cover (forbidden nowadays)

- 2.2) 00 class - ungrounded device with metal cover, which has earth leakage signalisation (alternators, old surgery appliences, trolleybuses)

- 2.3) 000 class - ungrounded device with metal cover, which has RCD/GFCI

- 2.4) 01 class - device with metal cover, where ground wire is connected artificially way (absolutely all railway transport)

- 2.5) 01+ class - device with metal cover, where ground wire is connected artificially way with RCD/GFCI

- 2.6) 1 class - grounded device with metal cover (chandeliers, light fixtures, streetlamps, HV pylons)

- 2.7) 1+ class - grounded device with metal cover, which has RCD/GFCI (washing machines, air compressors, etc.)

- 2.7.1) All sockets must be connected through RCD/GFCI!!!

- 2.7.2) All electric devices in wet rooms or outdoors must be connected through RCD/GFCI!!!

- 2.8) 2 class - device with dielectric cover (TV-sets, portable lamps, etc.)

- 2.9) 2+ class - device with dielectric cover, which has RCD/GFCI (TV-sets, portable lamps, etc. in new houses)

- 2.10) 3 class - extra low voltage devices, which are not danger for human (cars, watches, electronic thermometers, torches, etc.).

- 2.10.1) All light fixtures in bathrooms/showers/swimming pools must be lower, than 36 volts!!!

- 2.10.2) 12-volt LED light fixtures are best solution for bathrooms or showers =)

- 3) RCD/GFCI

If electric applience working with covered chasis, it means, that nobody will be electrocuted, cause load wires are hidden against touching by fingers. But imagine, if chasis is broken and anyone can put his fingers to hole to touch energized parts. Of course nobody will do it in sober minds... but some people continue to use electric appliences even with broken cover and as result get shocks being wondered. I don't know, what about they were thinking, but electricity doesn't forgive such negligence. Lot of homeowners use 230V shavers or hairdryers in bath or showers through extension cord. It is lethally danger, but only few homeowners realize the risks. As the company, who wired their home said words "safe and up to standarts", homeowners really forget about all risks.

Second reason are water pumps or washng machines. They have no transparent chasis and nobody can see, if the water is flooding energized wires. Also, usual circuit breaker can't trip, cause water has electrical resistance and short-circuit-current value won't be enough to beat out circuit breaker. Such way, lethal voltage will walk on pipes and someone from your neighbors may get lethal shock while taking shower.

In both cases we're talking when current "overshot" neutral wire and goes somewhere else. If the person has good health, shock wouldn't have serious consequences (e.x. I don't smoke or use drugs, even drink alcohol very rare and 230V electric shock comparable to a mosquito bite for me and I don't afraid it). But imagine persons with weak health - discharging capacitor (I mean widespread joke in primary schools) may cause heart fibrilations or something more serious, but short contact with 110V or 230V able to kill them.

As electrical engineering must consider the worst conditions, it means protecting against shocks, even when someone without brain dry hairs in bath. For this purposes is created RCD (in Europe) or GFCI (in America). It counts ampearge in hot and neutral wire - it will trip, if the first Kirchhoff's circuit law is enforced and amperage ballance between hot and neutral wires is missing. RCD/GFCIs are obvious for washing machines and other risky circuits, like bathrooms or outdoor appliences. Better to protect all the circuits on available for touching altitude, even if the building codes doesn't require. As the ceiling lights in dry rooms are fixed on high altitude, nobody able to touch them and protecting by RCD/GFCI will be useless waste of money.

- Where to work? Small company or big company?

As usual, small companies trying to save money on everything. There is working one person, who does job of 10 specialist alone and total price became as there worked only 3 persons. As result, quality of those work is too low... but lot of consumers have been seduced by low price! However, they have no possibilities to employ fresh specialists or use them as slaves without salary. After working for some months without money, workers can't proof anything at the court or contactor directed money into complex schemas, where even economical police is helpless.

Big companies are working like zoo in big city. I have quite big experience of working there and what problems are there: nothing is coordinated. Big company is divided into small departments: designing, engineering, constructing, wiring, etc... and nothing is done in command. They do for 2 weeks work, which might be done during one day! And after you have done volume of work for 2000 EUR, they pay you only 350 EUR as it was specified in the contract.

Of course, there are companies with coordinated work in command... but they are not latex and can't empoy everyone. As number of those companies is limited, they employ only best of the best specialists with big expirience.

Entrepreneurness has lot of underwater stones. Due to law, you should employ contactor and you can't do lot of works without helper. Imagine to line 4G120 cable under ground or constructing pylon alone =)

From consumer's position, cheap and quick work is attractive, but only few of them think about quality. That is why China and other Asian countries are economically prosperous and Europe living in crisis.

Videos[edit]

Here you can see "how to do it" by your own eyes and get some visual experience before going to work.

Wiring in living buildings:

How to join wires with too fat gauges:

Some images about safety[edit]

Work with electricity related with some risk. Not such risk as sound the alarm safety boards (as rule, they have purpose to take more money from national budget instead of taking care about safety). But you may get some serious traumas and sometimes even death. That is why it is need to follow safety rules. For example, don't ever touch energized parts or put your fingers into energized metal perts. If there are no possibility to remove the voltage, wear hot gloves and work by tools certified to voltage you're working with. If fuse exceeds 35A, avoid any short circuit at all, cause heat rejection can cause deep skin burns on your body or send you to hospital for a long time. You don't want to spend the rest of life in a wheelchair, is it so? Don't forget about your own safety.

How to NOT work with electrical wiring (videoexamples with rude enforcement of safety)

Golden rules[edit]

-

Power must be off before work!

-

Work in distribution substation is extremely danger!

- Small installations:

- 1) Before work turn power off!!!

- 2) Seal circuit breaker by lock!

- 3) Check your test light first and then check missing voltage on working place!

- 4) When power is off, short all hot wires into ground until you're working!

- 5) Check your working place - there shouldn't be any hazards for you!

- Industrial installations (like factory):

- 1) Before work turn power off!!! Switchgear should have vertical ray on marking.

- 2) Seal circuit breaker by lock!

- 3) Remove hot wires from circuit breaker!

- 4) Before removing the cover from distribution board, put protecting googles into eyes!

- 5) Check your test light first from energized circuit and then check missing voltage on working place!

- 6) When power is off, short all hot wires into ground until you're working!

- 7) Check your working place - there shouldn't be any hazards for you!

- Overhead powerline (or "air powerline"):

- 1) Power must be turned off!!! Your company owner should have valid disenergizing protocol from energy company.

- 2) Earthing device must be transparent and wires should be seen good!

- 3) Lifting basket should have valid certificate to your weight + 25%

- 4) Before lifting to powerline, earthing device should be connected with ground.

- 5) All hot wires should be shorted to earthing device while you're working.

- 6) Weather should be suitable to work on altitude.

- How to work with energized circuits:

- 1) Check your tools! Their insulation must handle 6 times more voltage!

- 2) Put dielectric gloves to your hands and skin-burn mask to your face!

- 3) Shield working place from unauthorized persons!

- 4) To avoid closing circuit, cover open parts by dielectric cover! Open might be only one pole!

- 5) Check your working place - there shouldn't be any hazards for you!

- 6) If you're working on high voltage, you must bond lifing basket with circuit where you're working and basket must be separated from the ground.

-

Where is the dangers hiding?

-

Basic protection. Like in construction place. Don't work at all in construction place, if earthing is missing. It is not safe. Lot of builders were killed by ungrounded devices. You're studing right now and go there to get some experience, so don't kill yourself in such young age, whole life waiting you in future.

-

How to replace knife fuses safe way? If you're replacing them under voltage, don't forget to wear right clothes!!! And always keep in your brian, that coil has self induction which forms arc at every disenergizing!!!

-

First aid to your mate (many thanks to Gregors)

-

What to do, if earthing is missing?

-

How does short-circuit affect on fuse characteristc?

-

Risk rate

-

You're gonna design some electric device or wiring somewhere? What should you consider?

-

Why you may be shocked even if you don't touch second wire

-

What shouldn't be done in earthing

-

How to wire bathroom? It is not so difficult, as it seems

-

You're gonna to work by crane? What should you know.

-

Protection against overheating and fire.

-

Complex and cheap protection against risks in one device.

-

Well, company employed by public services replaced outdated equipment. But they forgot about earthing and put PE-color to antenna wire.

-

Guess all of my profanity words, when I found, that ground wire is used as antenna wire and metal fuse box has no ground.

However, mature specialists like me ignore safety requirements to do their work quickly. Second reason is your employer, who always requiring to do work faster - by skiping safety actions and start work with lot of risks. Third big problem is doing works being intoxicated by alcohol.

For example, Estonia have accepted leadership to electrical works (like in west countries) in the end of 1990's, but even nowadays lot of electricians do their work under alcohol intoxication (like it was 40 years ago) and as result they get traumas very often by touching energized busbars barehandly or by making casual short-circuit. And however, chiefs can't track sitution with their performer-electricians, cause one licensed contactor leads on thousands of negligence specialists due to good salary. Such negligence neutralifies all leadership with safety requirements and causes traumas for working personal. As result, all safety regulations become senseless and workers still get same quantity of traumas.

Motors[edit]

Automatics[edit]

Why it is need? Well, lot of usual people can't differ, what work should be done by electrician and what work should be done by automatian. Even in highly developed Germany. If work is related with wires or other electrical devices, they always invite electricians. And even competent manufacturers write in their instructions, that their device could be installed only by electricians. And nobody from licensed electricians say, that this device could be installed by automatician or mechatronic. And as rule, they take up work that they are not qualified to do at all. As usual, such installations exist being improper.

Also authorities of highly developed countries can't differ where is automatics, where is mechatronics, where is electrical engineering and where is high voltage power lines lining.

Due to my philosophy, knowledges are not heavy load, which is difficult to bear. Once they will be useful. I have education in electrical engineering, but I'm loaded by works where are need to have knowledges from other trades.

Here are some simple things from automatics, which you may understand having electrician qualification:

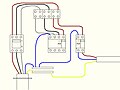

-

How to drive powerful load from small button?

-

The same for big fan

-

How to put the motor spin both ways?

-

What is about reversing with 4-pole contactors?

-

How to reverse the motor instantly?

-

How to spin powerful motor more faster? (only for Y↔Δ motors)

-

Driving DC motor using semiconductors

-

How does automation system looks like?

-

Symbols you can meet in automation diagrams.

-

Water heater

-

Underfloor heating

-

Basic diagram of sauna

-

How to put blink the LED's automatically?

-

Old Soviet tram arrow

-

Modern tram arrows

-

Trolleybus arrows

Semicondutors[edit]

One real story (happened in real life). It took place in the middle of 1970's in the village not far from Tallinn, while Estonia was the part of USSR. While electricians were repairing overhead power line, one of inhabitant had come and asked them to repair his radio receiver after their work. When village inhabitant was refused by those electricians, he complained to the all authorities to them with words: "What *** **** electricians had come, who couldn't repair my radio receiver?"

- Moral of this story: don't be such provincial, even if the rules doesn't require knowing of much more material.

-

What does it mean?

-

How does semiconductros work?

-

Structure

-

Electronic filters